1.Ball mill comprehensive introduction

1.Application

According to the use of the ENC product on industry, ball mills are widely used in cement, silicate products, building materials, refractory materials, fertilizers, black and non-ferrous metal, and glass, ceramics and other production industries. The ball mill is a key equipment for crushing or finely pulverizing large-volume materials. It can dry or wetly grind various ores and other grindable materials. Ball mills are widely used in mineral processing, building materials and chemical industries, and are divided into dry and wet grinding methods.

2.

Machine structure

The ball mill is composed of a horizontal rotating cylinder, a hollow shaft for feeding and discharging, and a grinding head. The rotating cylinder is provided with an abrasive body, the cylinder material is made of steel plate, and the steel frame supporting the cylinder is used for fixing, and the grinding body is generally The steel ball is loaded into the cylinder according to different diameters and a certain proportion. The grinding body can also be used for steel segments, and can be rotated at a certain speed to grind.

3.Abrasive theory

The material to be ground is ground into a hollow cylinder through a hollow journal opening, and the cylinder is filled with grinding media of various diameters (steel balls, steel bars or gravels, etc.). When the cylinder rotates around the horizontal axis at a certain rotation speed, the medium and the raw materials contained in the cylinder are separated from the cylinder by the centrifugal force and the friction force, and when the gravity reaches the certain height, when the gravity is greater than the centrifugal force. The body wall is thrown down or rolled down, crushing the ore due to impact. At the same time, during the rotation process, the sliding movement of the grinding media to each other also produces a grinding effect on the raw materials. The ground material is discharged through the hollow journal opening.

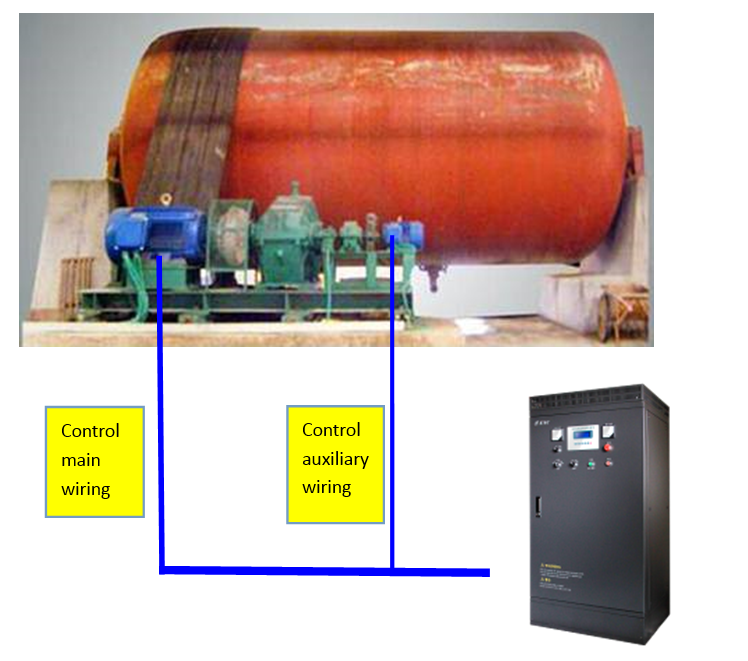

4.Main and Auxiliary Machine

The power for driving the cylinder to rotate is the main motor and the auxiliary motor. The main motor shaft rotates through the reducer and the belt, and the auxiliary motor and the main motor are interlocked. The auxiliary motor works when feeding or starting, as the auxiliary motor drives the drum at a slower bigger torque due to the secondary speed reduction mechanism.

5.Working process

When the raw material is loaded, the auxiliary motor is started to rotate at a slower speed, and the feeding port is rotated to a specific position to align the interface feeding. After the raw material is installed, the belt will slip if use main motor due to the precipitation of the raw material at the bottom directly. Use the auxiliary machine to work slowly for a period of time, shake the material evenly, and then use the main motor to quickly drive the drum to rotate.

2.Introduction of EN501 ball mill energy-saving integrated control cabinet

1.Introduction

EN501 series ball mill energy-saving integrated frequency conversion control cabinet is a smart energy-saving device developed for the ball mill application industry. The control cabinet is not only equipped with voltmeter, ammeter, DC reactor, liquid crystal display, etc., but also has developed a variety of parameters designed to meet the requirements of multi-ball milling according to the ball mill process/workflow requirements. In addition, the series is also designed with the main-auxiliary electrical control loop that can be used to meet the application of the main auxiliary machine.

2.

Type details

Input voltage | Frequency inverter model | Rated output current | Adapter main motor | Adapter auxiliary motor |

380V Three phase 380V | EN501-4T1600 | 304 ( A) | 160KW | 7.5KW |

EN501-4T2000 | 380 ( A) | 200KW | 11KW |

EN501-4T2500 | 474 ( A) | 250KW | 15KW |

EN501-4T3150 | 600 ( A) | 315KW | 18.5KW |

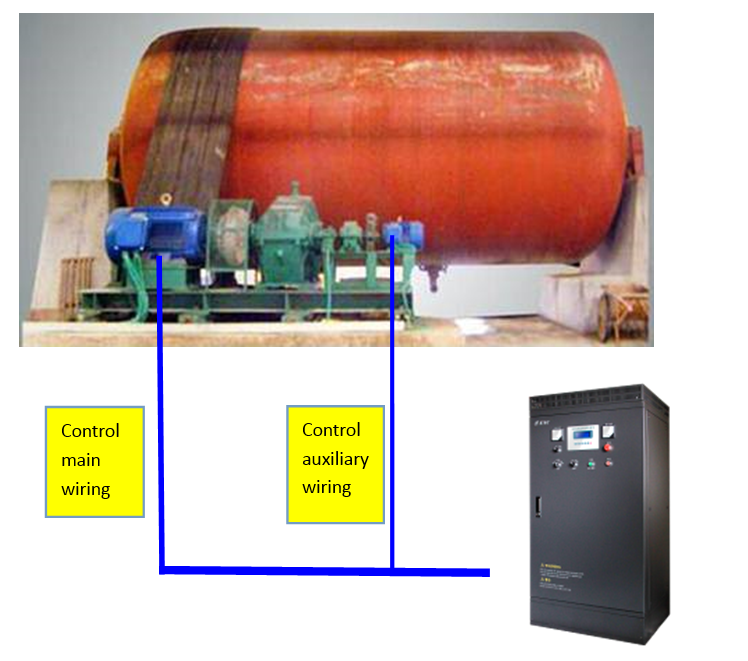

Figure 1

3.

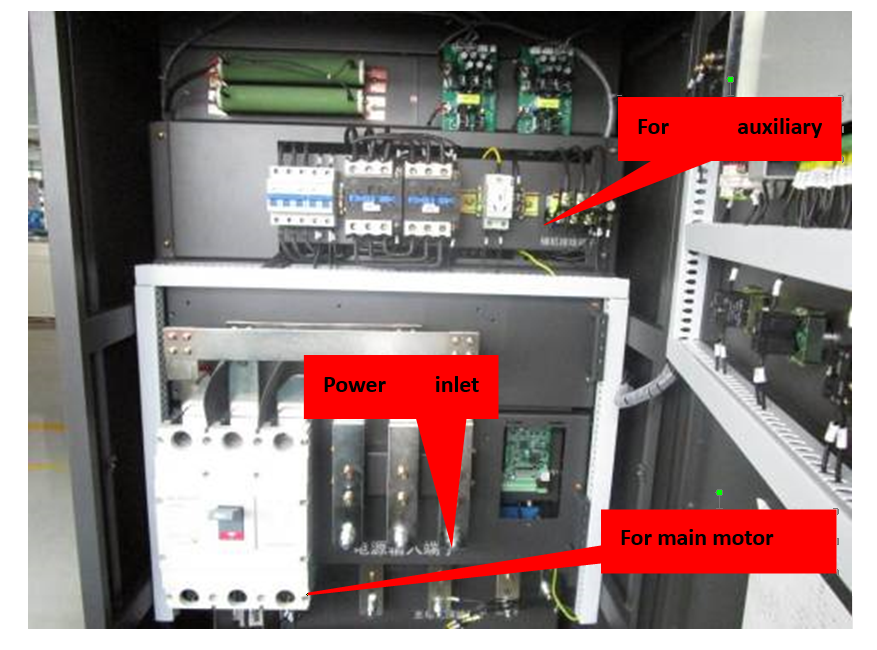

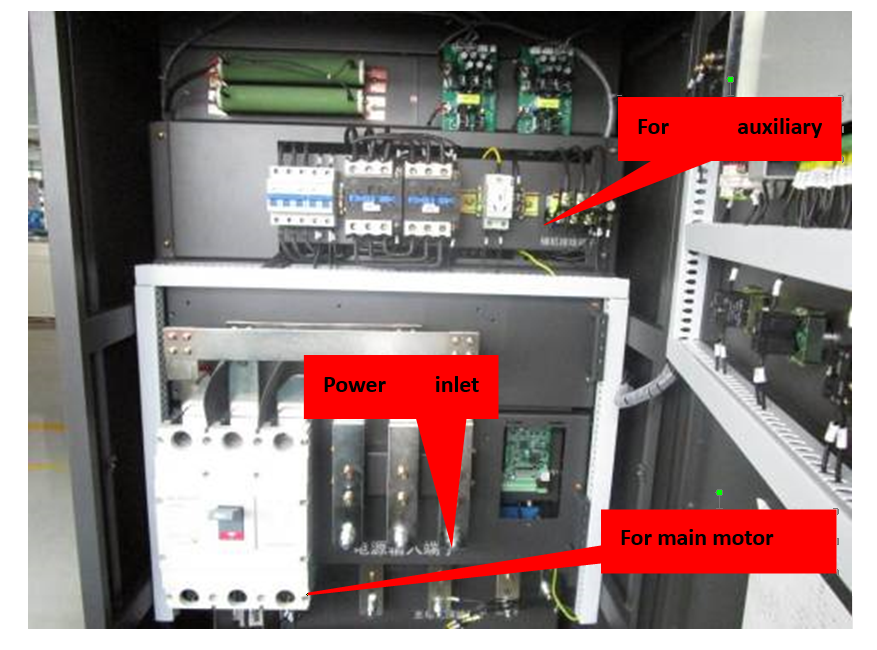

EN501 energy-saving integrated inverter control cabinet internal structure show:

The internal and external wiring of EN501 series energy-saving integrated inverter control cabinet include three parts that as follows: The wiring is easy to install and easy to operate.

(

1)

Power inlet terminal R/S/T

(

2)

Main motor terminal block U/V/W

(

3)

Auxiliary motor terminal block X/Y/Z

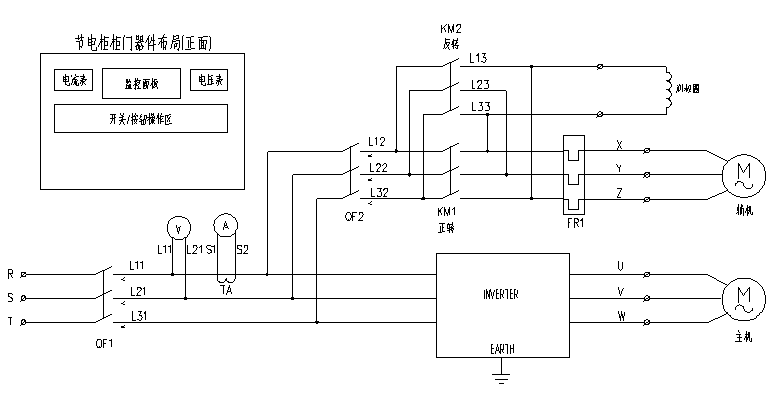

Picture 1, Inside wiring of the machine

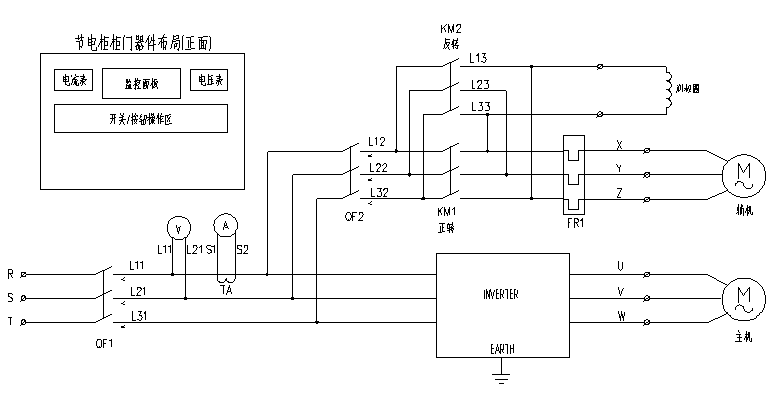

4.EN501 energy-saving integrated inverter control cabinet main circuit wiring schematic:

Figure 2, main circuit wiring schematic

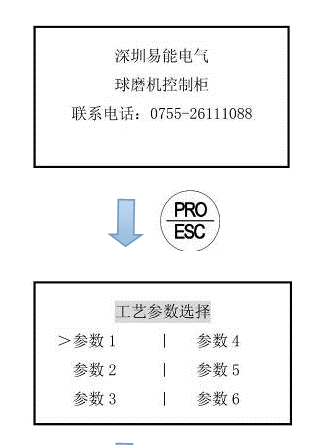

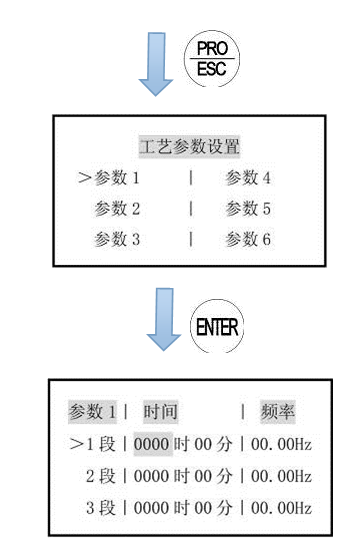

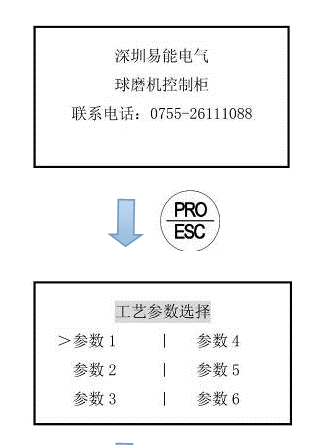

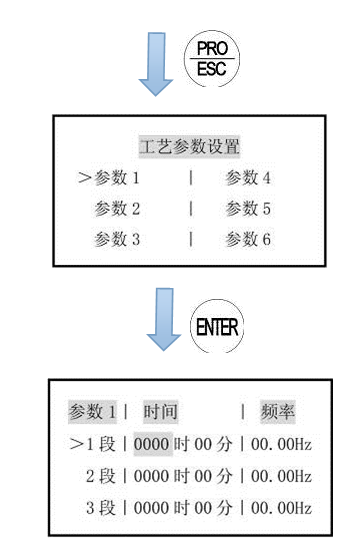

5.Process parameter setting and selection

(

1)

The process parameter group consists of 6 groups, parameters 1 to 6, and each parameter has 8 segments. Each segment has a running time and running frequency. See the table below:

Figure 2

(

2)

Interface selection and parameter Settings

Set and select the key  to enter the parameter selection interface,

to enter the parameter selection interface, select the parameter, press the key

select the parameter, press the key  to confirm and return to the main operation interface.

to confirm and return to the main operation interface.

Figure 4:Parameter setting flow chat

Press  t

o select interface segment, and

t

o select interface segment, and to select hour, minute and frequency

to select hour, minute and frequency

EN501

Ball mill special machine considerations

1.

Selection, wiring and parameter settings

Refer to Table 1 for the selection of the ball mill. For the wiring method, refer to the internal wiring terminal diagram and wiring schematic diagram of Figure 2 and Figure 3. Connect the wiring according to the instructions in the figure. After the wiring is completed, then set according to the requirements of the grinding process. For the setting method, refer to the parameter setting flowchart of Figure 4. The main setting is the value of each running time and running frequency.

2.Ball mill selection for special auxiliary machine configuration

?

In a few occasions, the power segment configuration of the main and auxiliary machines of the ball mill will exist in the following table.

Input voltage | Model | Rated input current | Adaptive main motor | Adaptive auxiliary motor |

380V Three phase 380V | EN501-4T1600 | 304 ( A) | 160KW | 11KW |

EN501-4T2000 | 380 ( A) | 200KW | 15KW |

EN501-4T2500 | 474 ( A) | 250KW | 18.5KW |

EN501-4T3150 | 600 ( A) | 315KW | 22KW |

Figure 3

If the above situation occurs, the auxiliary machine is larger than the standard configuration, and the product must be customized.

3.Startup considerations

?

(

1)Ball mill with auxiliary machine

Most ball mills have both a main motor and an auxiliary motor, and the auxiliary motor is used for starting and charging. After the ball mill is finished, start the auxiliary motor and work for about 5 minutes. Or after the material in the drum is shaken evenly, stop the auxiliary machine and switch to the working state of the main machine to work well. If the machine is running in the state of the main unit immediately after loading, a larger starting torque is required due to the sedimentation of the material, which will cause the belt to slip and damage the belt for a long time.

(

2)

Ball mill without auxiliary motor (rarely)

A few ball mills have no auxiliary machine. At the end of charging, or the drum with the material body is stopped for a long time, the bottom of the material is sedimented. At this time, the torque must be maximized when starting to rotate to 90 degrees. If the operation continues, the belt will slip or damage. That needs to stop the motor running immediately. The drum rotates to the opposite direction due to gravity. When the motor rotates again in the forward direction due to gravity, the inverter starts to work again with the speed tracking, such as swinging the swing mode, repeatedly honing, and going back and forth. The drum can be started up with a small torque after several times. With this kind of work position honing start, the drive needs to be set to free stop and speed tracking restart mode.

4.Advantages of the EN501 ball mill machine for ball mills

Energy-saving frequency conversion control cabinet special for ball mill application, integrated design, compact structure and easy installation.

Standard LCD display, simple and intuitive operation interface

The cabinet contains voltage and current meter for direct monitoring and display, and the LCD panel contains the number of main running segments, current and frequency display, and standard insert with built-in DC reactor and circuit breaker.

The parameters are rich in functions. There are 8 kinds of PLC functions set in 6 kinds of parameters. It can be set in advance and can be called directly when you want to use it. The midway stop will memorize the number of segments and the running time of the stop time. And can restart from the stop time or manually reset.

Adopting high-efficiency power-saving design, the comprehensive power-saving rate can reach 10%~40% (related to actual working conditions).

Main and auxiliary machine control, convenient and fast to switch.

The working sequence when the ball mill is in the normal mode can realize the time that the main machine must run after the auxiliary machine has been set for the time, and the time that the main machine operation is not required after the stop is over for a set time, preventing it from starting the report failure, and can also cancel this feature.

The password can be set on the LCD screen. Every time you modify the function in the LCD screen, you must change the password to prevent the staff from mishandling.

It can realize the flux vector control operation and meet the 0.5Hz/150% rated torque smooth output, ensuring the ball mill starts smoothly without failure, and the actual current is smaller than the V/F operation under normal conditions.

Unique dust-proof design to prevent dust from entering the inside of the machine. Independent air duct design for easy maintenance of cooling fans

Input phase loss protection, output phase loss protection, output phase-to-phase short circuit protection, output ground protection and other functions.

Automatic voltage regulation function, effectively prevent motor stator overvoltage and reduce motor heat.

Automatic current limiting and fast current limiting to prevent frequent over current fault trips.

Adopt optimized SVPWM vector control technology; the control accuracy is higher and more stable.

5.Live use description and picture

?

?

Mail

Mail Online Service

Online Service

?

?