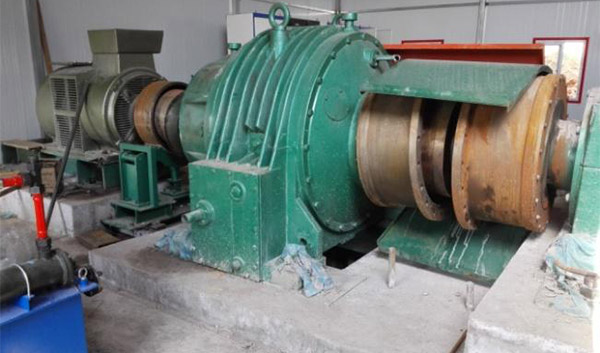

1.Overview for hoist

The hoist is also known as the winch, which can lift vertically, drag heavy objects horizontally or tilted, winding wire ropes or chains through a reel, and lifting or pulling heavy weight lifting equipment. The hoist is divided into three types: manual hoist, electric hoist and hydraulic hoist. Now the electric hoist is widely used, can be used alone, and also as a component of lifting, road building and mine hoisting machinery. The hoister has the advantages of high versatility, compact structure, small size, light weight, heavy lifting and convenient transfer. It is mainly used for material lifting or leveling of building materials, water conservancy projects, forestry, mines, wharves, etc.

The hoist saves a lot of manpower, material and risk costs, and improves the production efficiency. It is driven by motor, through elastic coupling, closed gear reducer, inlaid couplet drive reel, and adopt electromagnetic brake.

2.The shortage of traditional hoist control

The working requirements of the hoist are: slow starting speed, large torque, smooth acceleration, stable and accurate stopping. The conventional control adopts a winding rotor asynchronous motor, which controls the resistance by the collector ring and the carbon brush in the rotor loop, and controls the number of the accessed resistance by the contactor, but there are the following shortcomings:

1. The speed regulation is hopping, the gear reducer, the sky wheel, the middle wheel, the hopper and the guide rail are affected by the impact force during the acceleration and deceleration operation, the equipment is easily damaged and the wire rope is easy to fatigue, which leads to the large maintenance and the increase of the maintenance cost.

2. The speed adjustment range is small, stopping has higher inertia, difficult to debug and prone to offside and drop.

3. High energy consumption, most of the energy consumed on the resistor during the work .

4. Low speed mechanical characteristics are soft, the lower the speed, the softer the mechanical characteristics, the greater the energy proportion consumed in the resistance.

3.Application scheme of EN500/EN600 series used for hoist

1.EN500/EN600 Product Description:

The EN500/EN600 series high performance magnetic flow vector inverter adopt the advanced vector control algorithm to decompose the stator current into the torque current component and the excitation current component according to the coordinate transformation, so as to achieve accurate torque control, which has the advantages of good low frequency torque characteristics, fast dynamic response and high control precision.

Annotated: 55 kilowatts and below select EN600 series, more than 55 kilowatts select EN500 series.

The closed-loop 0HZ output keeps 180% torque, guarantees the motor torque during suspension starting and low-speed operation, and the speed regulation deviation is less than (+0.1%) synchronous speed.

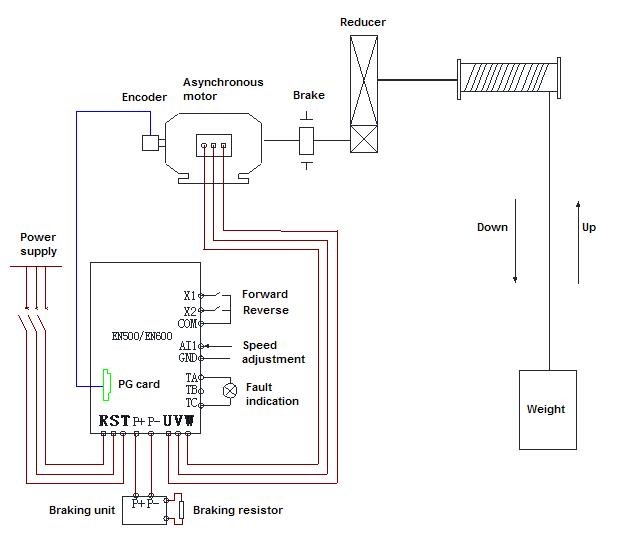

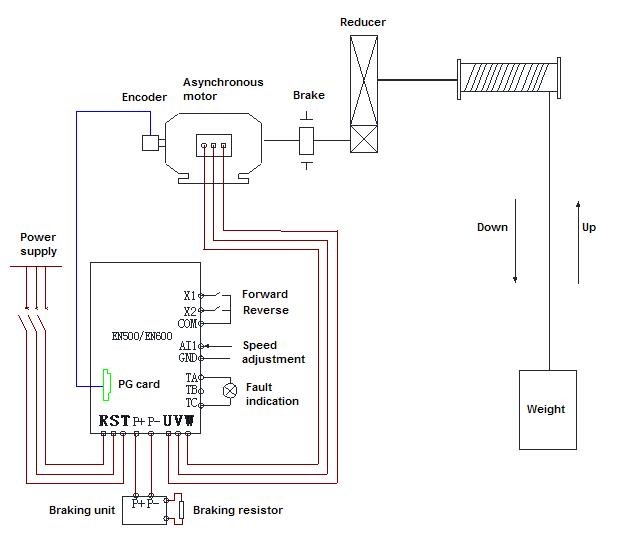

When the hoist is downward, the frequency inverter releases energy by converting the potential energy of the object at high position into electrical energy, which needs external brake unit and brake resistance to release energy.

2. The implementation of the hoist scheme

(1) Short circuit winding motor rotor winding, cancel the original series resistance speed regulation plan, or use ordinary three-phase asynchronous motor.

(2) Choose the appropriate incremental encoder to be installed in the rear part of the motor.

(3) The brake system is supplied independently and controlled by frequency inverter.

(4) frequency inverter selection should enlarge one or two level according to actual needs.

(5) EN500/EN600 output terminals are directly introduced into the motor inlet terminals.

(6) External braking unit and braking resistor are used for energy consumption braking.

The scheme can make good use of the original control system without changing the operating habits of the operators.

Figure 1 Wiring diagram for comprehensive control of hoist

3.EN500/600 parameters setting

Step 1: Self tuning parameter setting of closed loop vector

Function code |

Setting value |

Explanation |

F00.00 |

2 |

Select senior list mode |

F00.19 |

3 |

Incremental PG card |

F00.24 |

2 |

Speed sensor vector control |

F15.O1 |

Set according to motor spec |

Motor rated power |

F15.02 |

Set according to motor spec |

Motor rated voltage |

F15.03 |

Set according to motor spec |

Motor rated current |

F15.04 |

Set according to motor spec |

Motor rated frequency |

F15.05 |

Set according to motor spec |

Motor rated rotational speed |

F15.06 |

Set according to motor spec |

Number of motor pole pairs |

F15.19 |

2 |

Motor parameter self tuning |

Step 2: Encoder parameter setting

F16.01 |

0

~

100000 |

Encoder line number |

F16.02 |

00 |

Direction of encoder |

F16.03 |

1.00 |

Frequency division coefficient |

F16.04 |

5

~

100 |

Encoder filter coefficient |

Step 3: Application function parameter setting

F01.00 |

1 |

AI1 analog setting |

F01.15 |

1 |

Terminal run command control |

F01.17 |

20 |

Acceleration time 2S |

F01.18 |

20 |

Deceleration time 2S |

F02.22 |

1 |

Energy consumption braking |

F08.18 |

1 |

Forward running |

F08.19 |

2 |

Reverse running |

4.EN500/EN600 and traditional control compare:

?

No |

Item |

Traditional series resistance control |

EN500/EN600 scheme control |

1 |

Acc.and dec |

Overspeed and overwinding are easily caused by changes in load. |

It does not change with the load and improves production efficiency |

2 |

Mechanical shock |

Large mechanical impact during crawling |

Smooth operation without mechanical impact |

3 |

Power grid Impact |

The startup has great impact on the grid, and the starting current is 3~5 times the rated current. |

The output current at startup is about 1.2 times the rated current. |

4 |

Low speed crawling |

Low speed crawling is mainly controlled by brake control and is unstable |

Low speed crawling stability can operate smoothly at low speed at 0.1M/S. |

5 |

System energy saving |

Energy dissipation, the power dissipation on the resistance is great |

Energy saving is obvious, usually over 20% ~ 40% |

6 |

Brake shoe wear |

The braking is frequent and badly worn.

The dust is large |

The brake wear is less, the dust is reduced, and the duty environment is good |

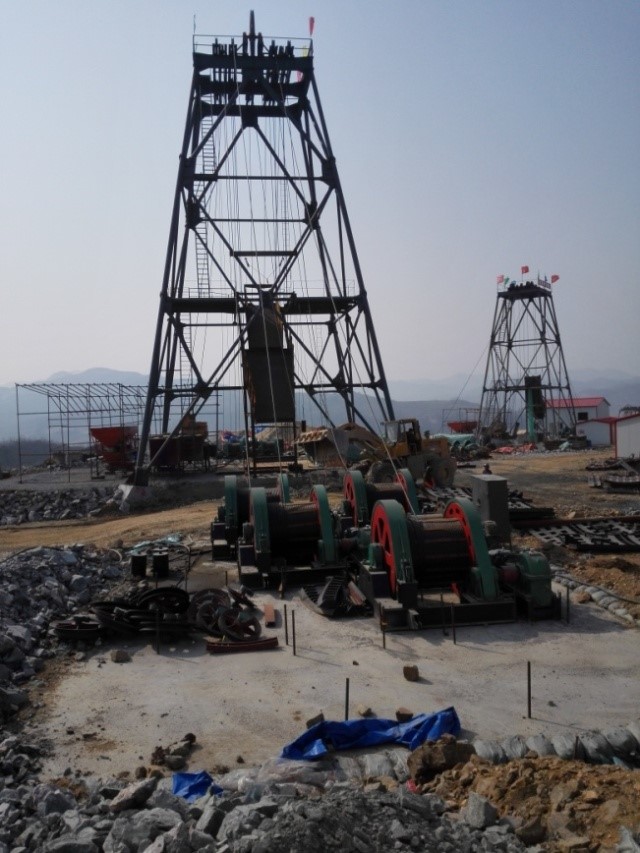

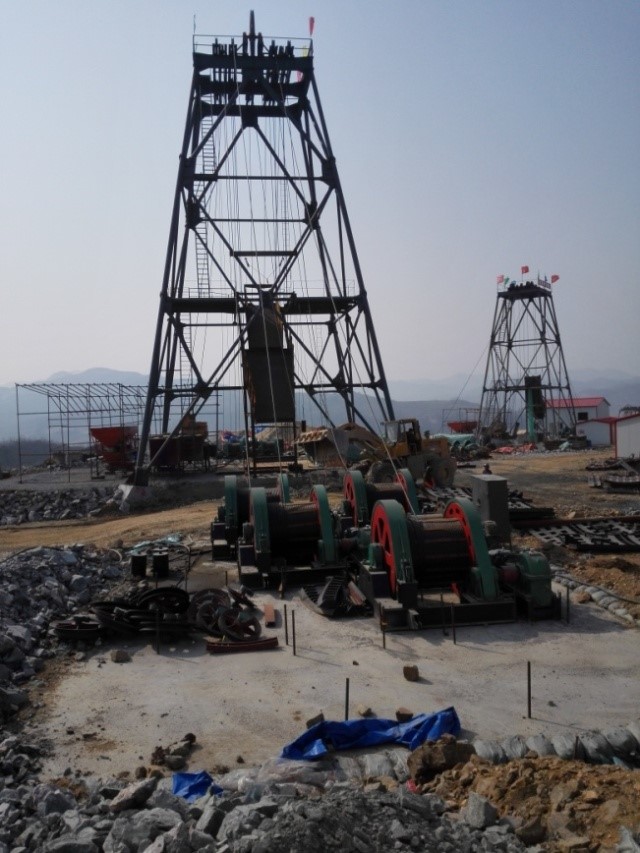

4.EN500/600 series used for hoist

1. EN500-4T6300G used for a mine hoist in Northeast China

2.EN500-4T2800G/P used for hoist in a smelting company in North China

?

?

?

?

Mail

Mail Online Service

Online Service