- Home

-

Products

-

Stable & accurate, efficient & safe

Encom has successfully launched a wide range of intelligent frequency inverter products which embody Encom unique technology. With independent intellectual property rights, the products performance can meet the wide requirements of various clients.

- Frequency inverter Industry special Inverter Industrial Control Optional Accessories

-

-

Solutions

-

Flexible , Ease-to-use, Convenient

Provide for customized solutions and one-stop service according to difference industries and requirements of customers. With specialized solutions to provide powerful support for new technology applications, improving production efficiency and making energy saving easily.

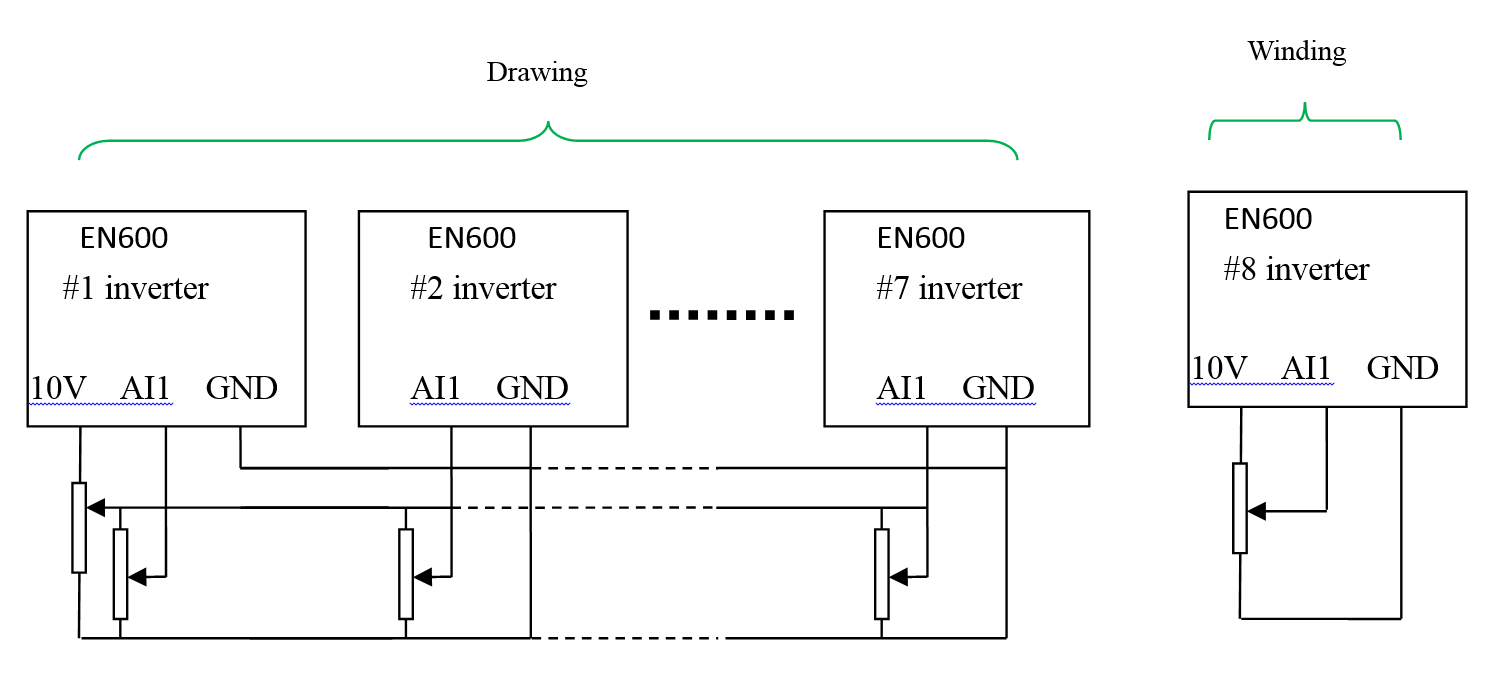

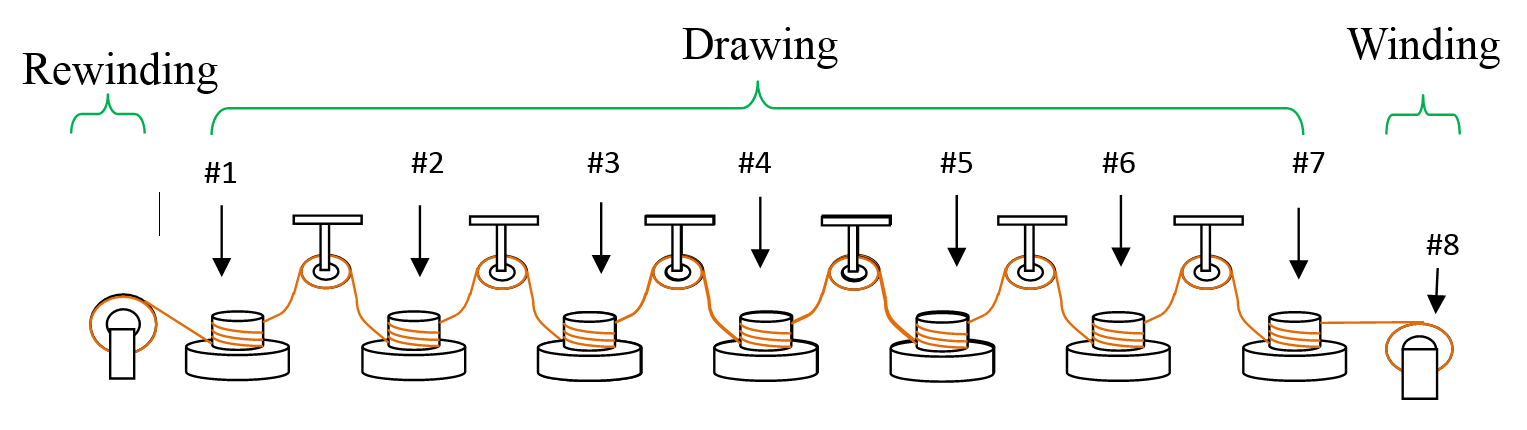

- Machining &fashioning Hoisting & Lifting Water supply& HVAC Chemical & Petroleum Wood working & Packing Washing & Dyeing Papermaking &Printing Molding & Compression Metallurgy & forging Winding & drawing Construction & Mines Textile & Chemical fiber Tobacco & Foods PMSM Applications More

-

-

Service&Support

-

High-efficiency & satisfactory

ENCOM knows well the importance of the perfect sales & service system, and regard distributor and user as the most importance cooperation partners. ENCOM build the normative market service network and mature technical service management system in domestic and can provide good pre-sale and after-sale service to distributor and user.

- ENC service Selection Guide Download FAQ Videos Online Service

-

-

About ENC

-

Energy conversion tech

Over 20 years development, ENC won the national innovation fund, strategic new industries fund, high-tech research subsidies, product innovation award, the most investment value award etc. and became "One of top 10 low voltage frequency inverter brands" continuously for several years.

- ENC profile Brand Story ENC Culture Qualification & Honor News Center Contact us

-

-

HR

-

Unite & Strive, Develop together

We focus on creating learning organizations.Improving employees' attitude and values by training so as to stimulate the potential of employees and improve the organizations and individuals’ performance.Promote the continuous progress of organizations and individuals and develop together.

- Talent concept Employee Benefits Career development Campus Recruiting ENC activities

-

- Contact Us

Mail

Mail Online Service

Online Service

?

?