1.Introduction of injection molding machine industry

Injection molding machine is also called injection moulding machine or injection machine. It is the main molding equipment that makes thermoplastic or thermosetting plastic into plastic products of various shapes by using plastic molding molds.

Figure 1. Injection molding machine

2.Where are injection molded parts applied to:

Injection molded parts are widely used in mobile phones, plastic enclosures, telecom, home appliances, computers, industrial appliances, electronics, toys, watches, lighting, locomotives and other industries.

Figure 2. Injection molded parts

3.Molding process of injection molding machine

1.The composition of the oil way

The hydraulic transmission device in injection molding machine is mainly composed of oil pump, hydraulic control valve, pressure electromagnetic proportional valve, flow electromagnetic proportional valve, and various execute oil cylinder, oil pump motor, other hydraulic accessories and pipes. The oil pump motor drives the oil pump to rotate at high speed, providing a certain pressure and flow of hydraulic oil to the oil system to meet the requirements of driving load.

2.The cycle of injection molding

The injection molding machine can produce the injection parts according to the predetermined periodic movement. One cycle is divided into: clamping, nozzle forward, glue injection, packing, sol, cooling, opening module, ejection finished products, ejector rod back, closing. The hydraulic oil system of the injection molding machine ensures that the injection molding machine works accurately and effectively according to the requirements (pressure, speed, temperature, time, position) and the operation procedures of each predetermined process.

3.Description of injection molding machine process steps

The injection molding machine uses the thermoplasticity of plastics, melts by proper heating, and then flows into the mold cavity rapidly with high pressure for a certain period of time to keep the pressure and cool down. Become a variety of formed material and plastic products. The process steps are as follows:

1) Clamping and high pressure clamping: when the template is fast close to the fixed template, and no foreign body exist, the system turns to high pressure, locking the template;

2) The injection table is forward: the nozzle is tightly attached to the mold;

3) Glue injection, injection: injection screw with a certain pressure and speed of melt into the front of the barrel cavity;

4) Keep the pressure and cooling: the plastic products in the mold cavity can be cooled down through this action.

5) Premoulding: Traditionally, hydraulic motors are used to drive the screw back, and the plastic particles added to the hopper are pushed forward for pre-moulding. Screw back to the predetermined position, stop rotating and prepare for the next injection;

6) The injection table retreats and opens the mold.

7) Thimble top out the finished product.

4.EN606 for injection molding machine application

1. EN606 control wiring is as follows:

1) Main circuit: R/S/T is connected to the power supply, and U/V/W is connected to the motor.

2) Control circuit: EN606 has the function of receiving voltage and current analog signals. If the flow signal and pressure signal are 0-10V voltage signals, then they are connected to V1-C1 and V2-C2 terminals. If the flow signal and pressure signal are 0-1A current signal, then they are connected to I1-C1 and I2-C2 terminals.

Figure 3. EN606 system control chart

2.EN606 main parameter settings

Vector control parameter settings

Function code | Setting value | Explanation |

F01.15 | 1 | Terminal run command control |

F01.17 | 10 | Acceleration time 1s |

F01.18 | 10 | Deceleration time 1s |

F22.00 | 1 | User customized mode 1 |

F22.01 | 0010 | Pressure provision curve 1 Flow provision curve 2 |

F22.10 | 10 | Curve 1 minimum input value point A0 |

F22.11 | 0 | Curve 1 input point A0’s corresponding per unit value B0 |

F22.16 | 70 | Curve 1 maximum input value point A3 |

F22.17 | 100 | Curve 1 input point A3’s corresponding per unit value B3 |

F23.00 | 10 | Curve 2 minimum input value point A0 |

F23.01 | 0 | Curve 2 input point A0’s corresponding per unit value B0 |

F23.06 | 70 | Curve 2 maximum input value point A3 |

F23.07 | 100 | Curve 2 input point A3’s corresponding per unit value B3 |

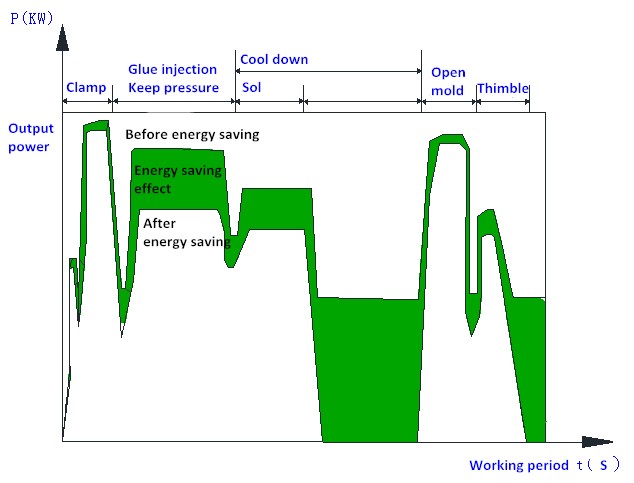

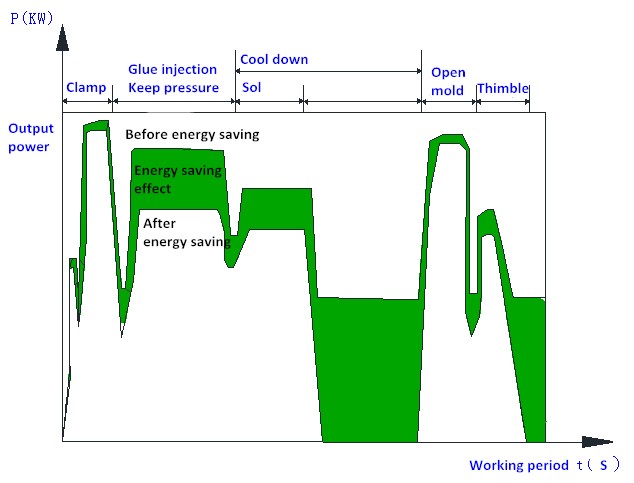

3.Comparison of energy saving effect

Figure 4. EN606 energy saving effect chart

4.Advantages of using EN606 for injection molding machine application

n EN606 series integrated machine design, built in power frequency / frequency conversion circuit, more reliable.

n The advanced flux vector control technology has the advantages of fast speed response, super overload capacity and low EMC interference.

n

Accept the dual channel analog voltage / current input signal of pressure and flow of injection molding machine.

n Multiple curve point voltage / frequency curve setting, multi curve selection can achieve the best energy saving effect.

n Accurate control, short acceleration and deceleration time, quick response, no reduction in production efficiency and high production efficiency.

n Two way isolation 0 ~ 1A/0 ~ 10V analog input, applicable to a wide range of models. ;

n The comprehensive electricity saving rate is 20% to 60%.

5.EN606 field application photos

6.Concluding remarks

?

The application scheme of EN606 has been widely used in many places. The product has excellent performance advantages and original advanced flux vector control algorithm, which can make the motor output torque powerful, fast response speed, realize 0.1s acceleration; the EN606 has fast current limiting ability, and can be stable running without over current. EN606 integrates a unique injection molding machine control process, provides two separate mutually isolated channels (voltage or current), and can directly interface with the injection molding machine. The software has a three-way process curve memory function, so there is no need to change the parameters when changing the mold. Good application results have been obtained in general, the power saving rate is generally up to 30% ~ 70%; simple installation, no need to replace the motor and oil pump, short payback period.

Mail

Mail Online Service

Online Service